3DCP SOLUTIONS

zum Wohle aller3DCP SOLUTIONS

zum Wohle allerWith our 3DCP system and other technologies, we can

up to 20 – 30 times faster.

A 250 m2 house in skeleton construction can be

in 24 – 48 hours

be erected.

We need fewer workers,

no molds for concrete,

and no steel.

As we use faster hardening cement,

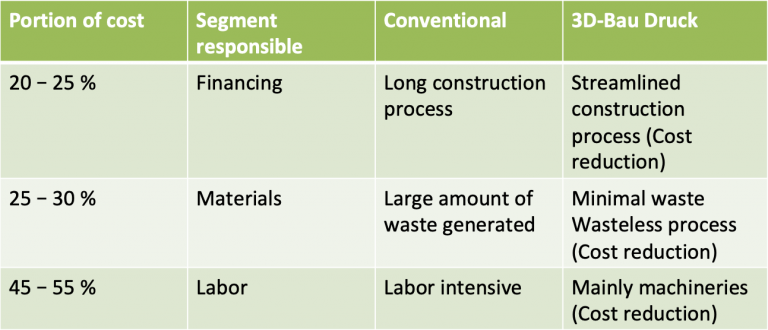

we can save up to 35 % of the costs.

As we do not use heavy machinery, not only is the construction site safer, but also the building itself, because it is:

fireproof

waterproof

Chemical resistant

etc.

Because we use geopolymer cement and basalt (and no steel at all)

our structures are up to 6 times stronger

than Portland concrete/steel constructions.

Also because we do not use steel, our constructions last longer.

This means: no rust, corrosion or expansion as with steel,

which in turn means:

no cracks, fractures or other damage to the concrete structure over time due to rust and more resistant to earthquakes.

As we do not use Portland cement, we produce

75 to 85 % less CO2.

Because we don’t need steel retaining walls or other forms, when the project is completed we have

generates up to 0 % waste.

The second most used material on the planet is concrete (water is No. 1)

Over 4 billion tons of concrete were produced in 2018

For every ton of concrete produced, 0.75 to 0.85 tons of CO2 are released into our planet’s atmosphere. That was 3.2 billion tons of CO2 in 2018.

The production of Portland cement is equivalent to the output of 5.81 billion cars. These are all cars in Europe, America and China.

We would have to create 107,242 square kilometers of forest to process this amount. That is about 1.5 times the size of Ireland.

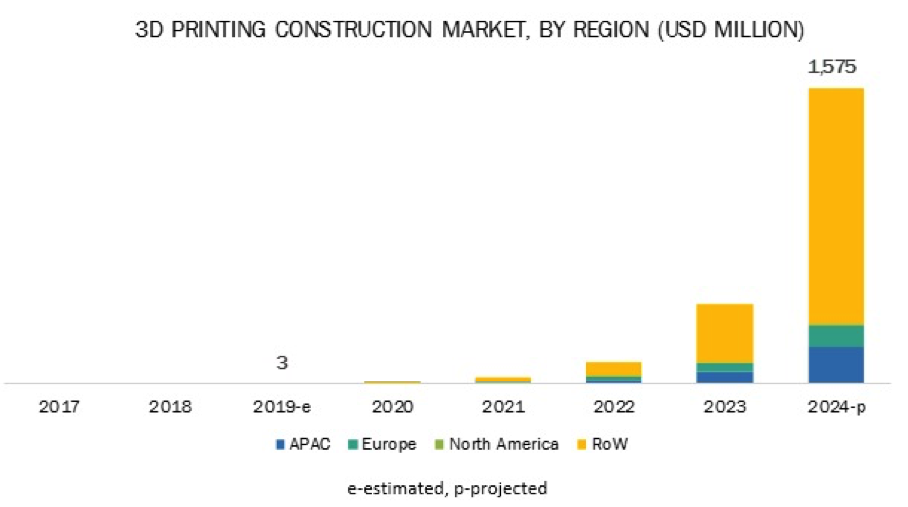

According to reliable sources, the 3DCP industry is expected to grow by over 245.9% per year between 2020 and 2024. These include McKinsey, Businesswire, Architect Magazine, Markets-and-Markets and experts from the construction industry.

Our goal

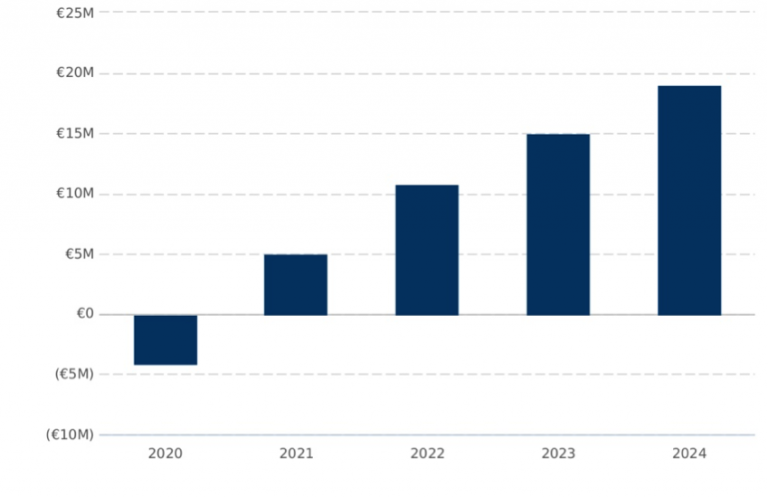

is to obtain up to 25 % or more of this market, depending on financing and investors.

We hope to grow to a value of over 1 billion euros in 5 to 10 years.

In this new and exciting industry, this is very possible and likely.

The 3DCP market is very small and very new, it is still at a very, very early stage. There are currently only about 10 companies worldwide that specialize in 3DCP, and only about 10 houses worldwide have been built with 3DCP.

The geopolymers we use, combined with the unique way we use them, ensure that our structures are better insulated against:

HEAT, COLD, WATER and MOISTURE or DRYNESS.

This means lower costs for heating and air conditioning and less water damage, which can be reduced to zero.

The geopolymers and other building materials we use are all hypoallergenic.

This makes life easier for allergy sufferers, making our homes a safe and healthy environment for your family or employees.

Because we use 3D printers

we can build more precisely. Unlike humans, robots build with 100% precision.

For this reason, we are also much more flexible in our choice of designs.

We LOVE what we do and are enthusiastic about our work. We want better, safer and more environmentally friendly homes to be built faster for less money. We want to build bespoke houses: Large houses for the wealthy, comfortable houses for the middle class and houses for the poor. We want to help people who would not normally be able to afford a house to build their home with us. We also plan to build houses in third world countries for the poor, using safer, cheaper and faster methods that are environmentally friendly. We currently have potential projects in Africa and South America. We want to help as many people as possible around the world to have a home of their own.

The following video should give you an impression of what is possible with 3D construction printing. The shell of the 115 square meter house shown here can be built in just 10-15 hours using our 3D printing construction system.

PLEASE VIEW IN 720 HD

If you have the following options for constructing your building:

…what are you waiting for?

Source: Mallorca Magazine (February 20-26, 2020)

We work with architects, engineers, contractors and experts to become the leading 3DCP company in the construction industry. We have many partners (including but not limited to): Geopolymer cement chemists as well as experts and scientists in other materials, 3D programmers, mechanical engineers, CAD experts, architects, civil and structural engineers, real estate agents, construction companies and experts, project planners for large residential areas in Germany, Spain, Africa, South America and the Middle East, as well as building permit specialist in the above mentioned countries.

If you are interested in growing with us and building a better future, please contact us.